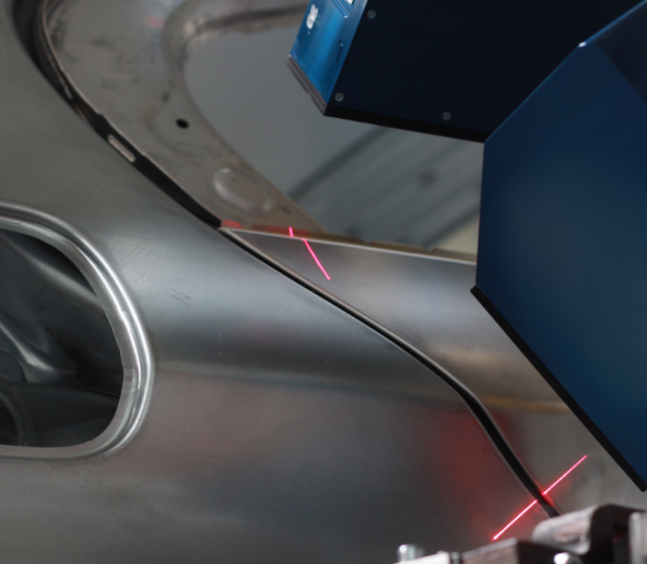

The goal of Gap & Flush is to achieve stable measurement of gap and flush values. When measuring gaps and transitions, the components to be measured often experience fluctuations that can affect the measurement results, such as variations in fold radius. Gap & Flush provides the solution by utilizing the VarioGauge DH sensor and the use of software.

The metrology VarioGauge DH (Double Head Sensor) is designed to be able to look deeper into the gap and to achieve a much more stable measurement on the radius edges of the components.

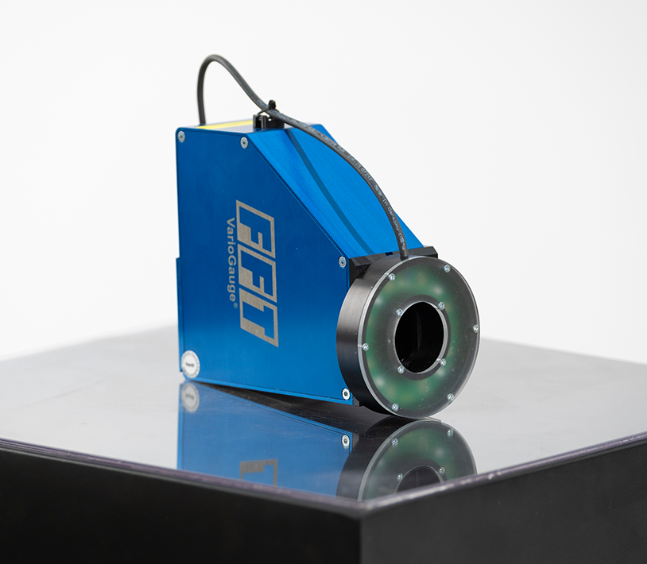

The VarioGauge VG6 2D (Ring light Sensoric) is the standard 2D camera solution for measuring holes. The sensor has additional light options. It has a high durability and an optical resolution of 0,05 mm per pixel.

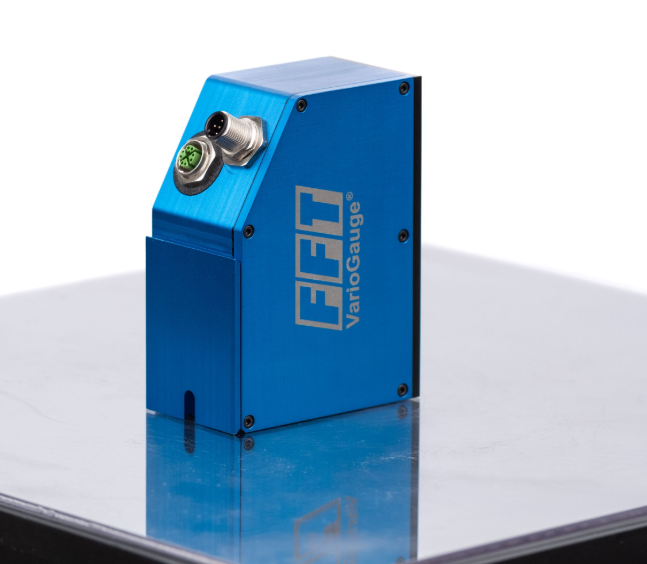

The VarioGauge VG6 2.5D (Triangulation Sensor) is the FFT standard 2.5D Sensor for edge detection and measuring gap and flush like the FFT DH. It has a high durability and an optical resolution of 0,05 mm per pixel like the FFT 2D sensor.

The VarioGauge VG7 2.5D is the new generation of FFT Triangulation Sensor and replaces the VarioGauge VG6 2.5D. It has a smaller housing and has a better resolution.

The VarioGauge HUB is an industrial-standard solution with very high availability. This HUB is designed for continuous use on the robot gripper. Several sensors, including different sensors, can be connected.

The Blue (Laser Scanner) for different applications. The Blue has a blue laser (405 nm), a high scan rate and a very small size. It can be used if only small space is available.

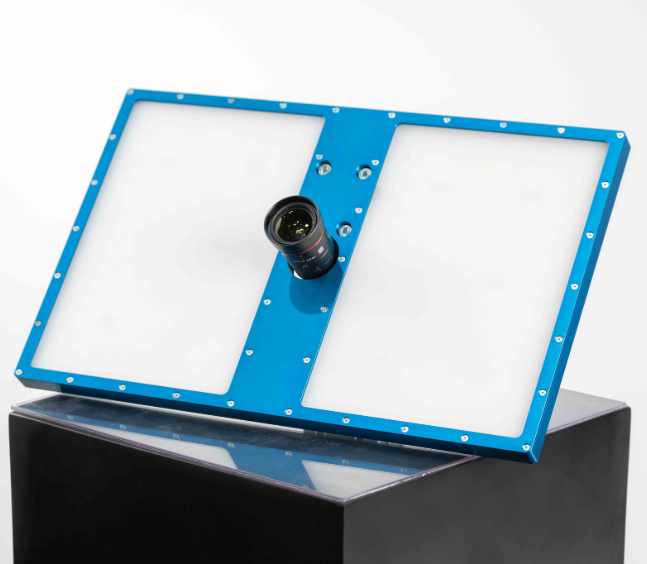

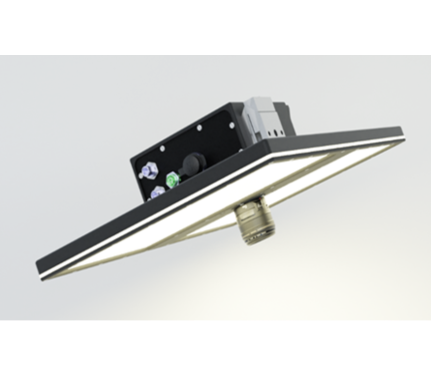

The VarioGauge Camera Panel is a camera with a light panel for different applications. This device is the perfect solution for standard TPC and RGS as a 2D system.

The VarioIC is a µC (integrated micro controller) based solution for several applications. With this micro controller a PC is not necessary. This system can be used for RGS (robot guiding system).

The Pipeline Inspection Gauge (PIG) is the solution for detecting small leakages in pipelines. The detection system is available in various diameters and fulfils all necessary TÜV demands.

The AI Panel is a device with controller, camera, lighting, Nvidia Jetson, hardware-accelerated by CUDA (GPU). The AI Panel is used for AI Check, -Ident and -Pick. No PC is needed.

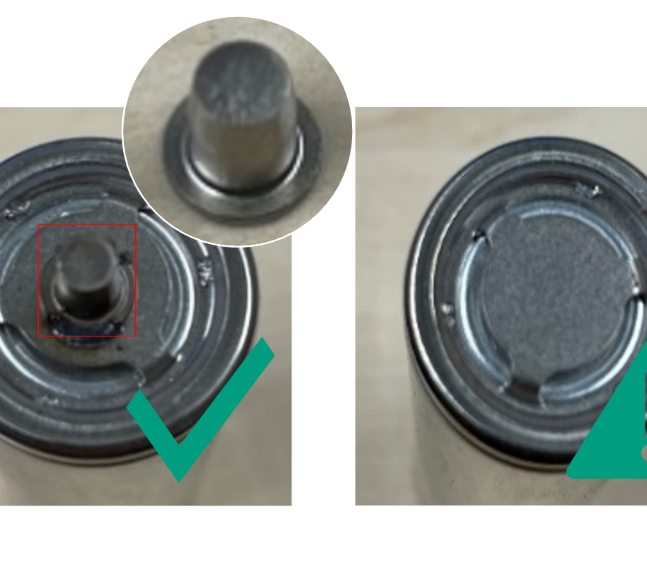

The AI Ident identifies and checks if parts are present, at the right position in the defined characteristics. AI Ident uses AI routines to create a stable system.

The AI Check is to find out, if parts are present or not and if the parts are geometrical ok.

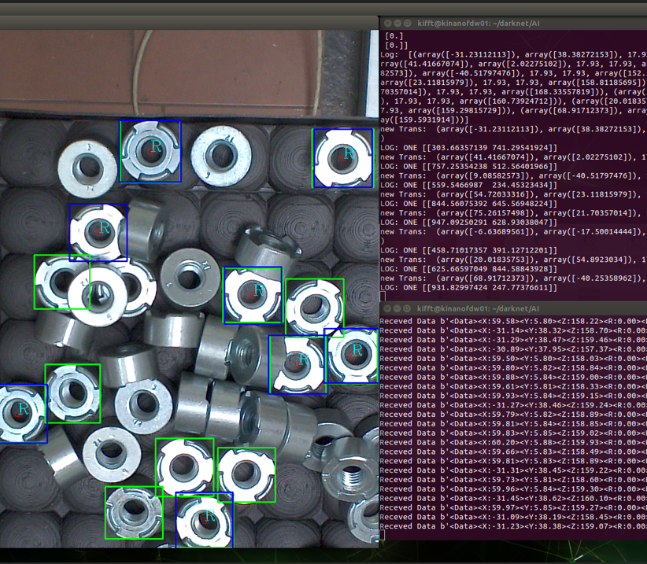

The AI Pick is used to identify parts, send their position including rotation information to a robot – which then can pick up the parts. FFT AI Pick uses artificial intelligence.

The Shapescan is the basic scanning solution in which the sensor is guided by the robot over the component to be tested, or the robot guides the component under the stationary fixed sensor. Examples are Bead Control and HemQC.

The BeadControl scans the adhesive bead in 3D and detects position, width and height. Measurements are taken during the process which means no cycle time loss.

Recently, Easun Technology has discovered that illegal individuals have impersonated our company to post fraudulent recruitment information on platforms such as Zhaopin (智联招聘) and Liepin (猎聘). To protect the legitimate rights and interests of job seekers, we hereby solemnly declare:

1. All official recruitment information from Easun Technology is exclusively released through our official website and verified accounts on recruitment platforms. We strongly advise job seekers to verify information solely through these authorized channels and to remain vigilant against unverified sources.

2. Do not disclose personal information (including but not limited to ID numbers, bank accounts, or contact details) to any unofficial channels. Unauthorized sharing may lead to potential risks or financial losses. No fees or transfers are required during Easun Technology’s recruitment process. If any party requests payment under the guise of recruitment, cease communication immediately and report the incident to local authorities.

3. Legal actions are underway: We have formally reported these fraudulent activities to the public security authorities and will fully cooperate with investigations to hold accountable those responsible for violating the law.

4. Easun Technology remains committed to providing authentic and reliable employment opportunities and safeguarding a trustworthy recruitment ecosystem. We appreciate your continued support and vigilance.

Issued by: Easun Technology

Date: 7 Jan 2025