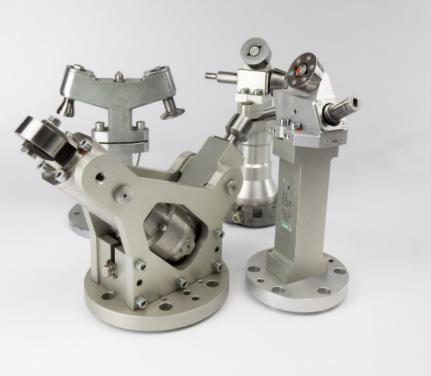

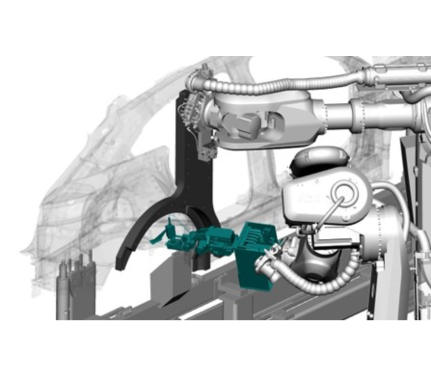

The modular design of the Single allows for a variety of different configurations. All variants are robot operated tools, made of a standardized basic housing with integrated force measurement load cell and a roller bracket for up to three hemming rollers. Its flexibility allows several derivatives to be operated in the same production line.

This roller hemming tool is mainly used for automotive hang-on part production, hemming flat, rope and special geometries made of steel and aluminum.

The Single S is a spring suspended roller hemming head. Its modular design offers a large variety of different configurations.

The Single F is a ridgid roller hemming head. Its modular design offers a large variety of different configurations.

The Single Y is a roller hemming head, which provides optimised access for curved parts.

The Single SA is a customized roller hemming head solution with individual designs according to your requirements.

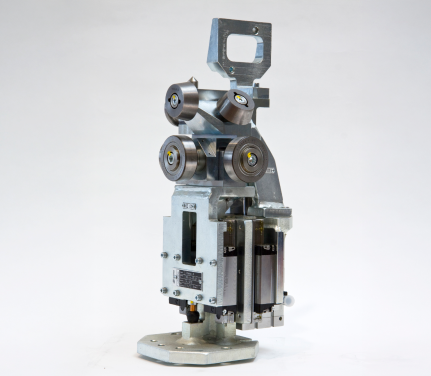

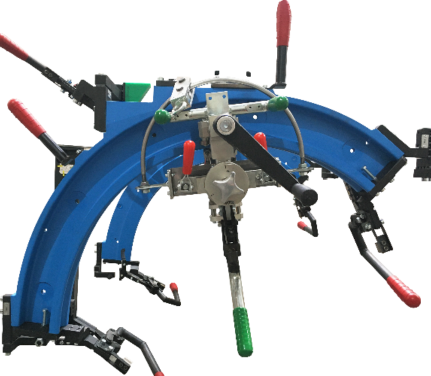

The Twinstep roller hemming head is a robot-guided tool for creating various hemming geometries. It consists of a standardized base body with two hemming rollers running one behind the other and an integrated force measurement load cell. Due to the arrangement of the hemming rollers, two hemming steps can be realized in one pass.

Its flexibility allows it to process several derivatives in the same production line. The Twinstep is used for various hemming geometries for steel & aluminum parts.

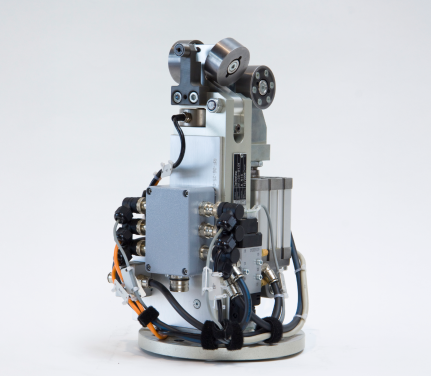

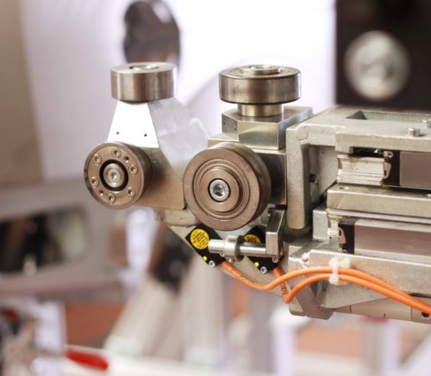

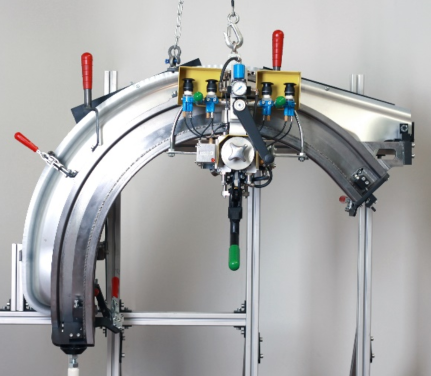

The Verso roller hemming head is a robot-guided tool consisting of a standardized base body with up to four pairs of hemming rollers. With this hemming principle, one roller performs hemming and the second roller absorbs the resulting force. The counter-roller principle creates a closed force system.

The roller hemming head floats in one direction [e.g. vehicle Y] by means of pneumatic compensation. The hemming pressure for the final hemming is controlled by a directional or proportional valve. The roller hemming tool is mainly used for wheel arch and door aperture hemming. Its flexibility allows it to process several derivatives in the same production line

The VersoA2 roller hemming system is used in automated production lines for side panel / wheel arch area. The system consists of the hemtec Verso roller hemming head and a type-specific hemming frame. Optionally, the roller hemming head is attached to the robot via a tool carrier (one-robot system) or is guided by a separate hemming robot (two-robot system).

Its flexibility allows it to handle several derivatives in the same production line.

The VersoA4 is an automatic wheel arch hemming system using two robots, a hemming frame and a roller hemming head.

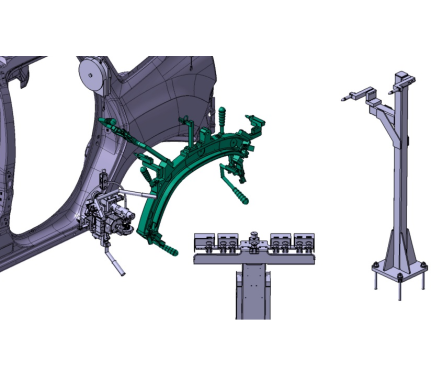

The VersoM roller hemming system is used in the side panel / wheel arch area. The system can be used in prototype manufacturing, pre- or small series as well as in manual serial production. One worker is operating the system. The roller hemming head is driven by a hand crank. Optionally, this drive can be pneumatic (VersoMP). A lightweight version (VersoML) is also available. Components of the system are the manual roller hemming head and a type-specific hemming frame.

The roller hemming head can be used flexibly for several derivatives.

The VersoMP roller hemming system is used in the side panel / wheel arch area. The system can be used in prototype manufacturing, pre- or small series as well as in manual serial production. One worker is operating the system. The roller hemming head is driven pneumatically. Optionally, this drive can be done with a hand crank (VersoM).

The system consists of a manual roller hemming head and a type-specific hemming frame. The roller hemming head can be used flexibly for several derivatives.

The VersoML roller hemming system is used in the side panel / wheel arch area. Special features of the system are the completely manual roller hemming head and its plastic hemming bed. The system is used in prototyping, pre-series production or small series. One worker is operating the System. The roller hemming head is driven by a hand crank. For series production we recommend our VersoM or VersoMP.

Components of the system are the manual roller hemming head and a type-specific hemming frame. The roller hemming head can be used flexibly for several derivatives.

The 180° roller hemming head is a robot tool. Depending on the application, it consists of a base body with 1-5 hemming rollers. It is used in sun roof hemming, in the pre-hemming process for hang on parts and in hemming without a countervail with a max. flange opening angle of 180° - Sunroof.

This roller hemming head can be used robot-guided or stationary. In the robot-guided process, the 180° is guided along the part by the robot. In the flying process, the part is guided along the roller hemming head by the robot.

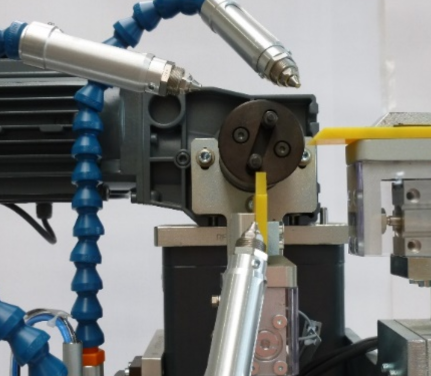

The Roller Cleaner automatically cleans contaminated hemming rollers without interrupting the automated production process. To start the cleaning process, the robot aligns the hemming roller in front of the drive element. Spring loaded pins on the drive element connect to the hemming roller to rotate it. The electric motor rotates the drive element and the hemming roller. The hemming roller is coated with a minimum amount of oil. A scraper removes the sticking glue.

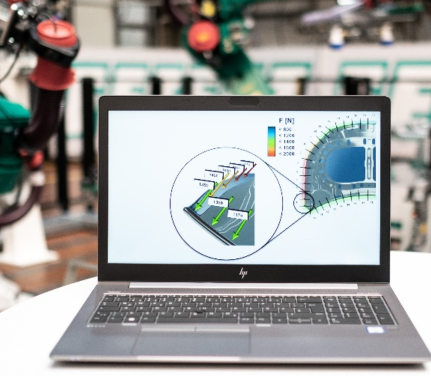

HemQC performs quality measurement on various types of hemmed shapes and contours. The latest HemQC system not only monitors the dimensions of hemming quality but also integrates with the hemming system to detect pressure. All data can be uploaded to the upper computer for corresponding control and can also be connected to the normal quality system for data integration.

Recently, Easun Technology has discovered that illegal individuals have impersonated our company to post fraudulent recruitment information on platforms such as Zhaopin (智联招聘) and Liepin (猎聘). To protect the legitimate rights and interests of job seekers, we hereby solemnly declare:

1. All official recruitment information from Easun Technology is exclusively released through our official website and verified accounts on recruitment platforms. We strongly advise job seekers to verify information solely through these authorized channels and to remain vigilant against unverified sources.

2. Do not disclose personal information (including but not limited to ID numbers, bank accounts, or contact details) to any unofficial channels. Unauthorized sharing may lead to potential risks or financial losses. No fees or transfers are required during Easun Technology’s recruitment process. If any party requests payment under the guise of recruitment, cease communication immediately and report the incident to local authorities.

3. Legal actions are underway: We have formally reported these fraudulent activities to the public security authorities and will fully cooperate with investigations to hold accountable those responsible for violating the law.

4. Easun Technology remains committed to providing authentic and reliable employment opportunities and safeguarding a trustworthy recruitment ecosystem. We appreciate your continued support and vigilance.

Issued by: Easun Technology

Date: 7 Jan 2025