Our welding tools for industrial joining technology can be customized for assemblies such as motors and transformers. We offer three different welding guns, which differ in welding force and weight.

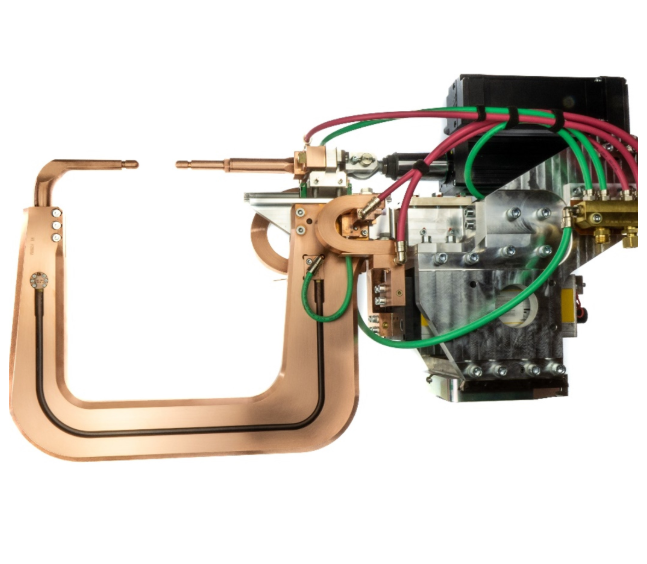

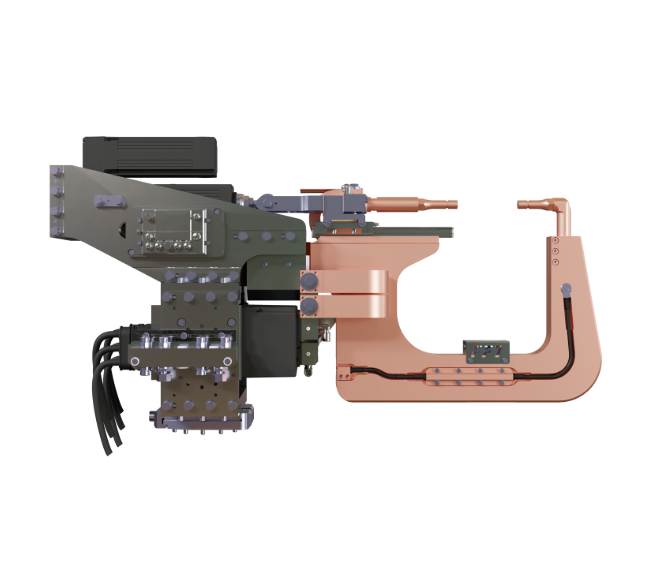

The Basic C-Gun is a robot welding gun for steel welding with C-frame and a max. welding force of 6.000N.

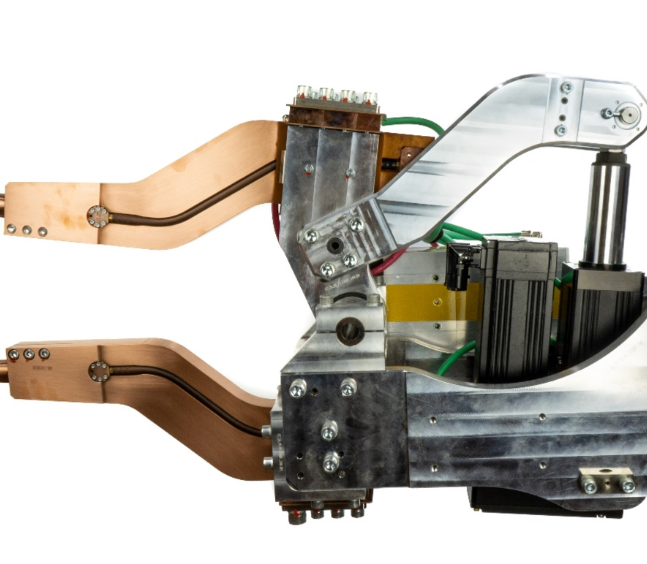

The Basic X-Gun is a robot welding gun for steel welding with X-frame and scissor-like electrode arms. The max. welding force is 5.000N.

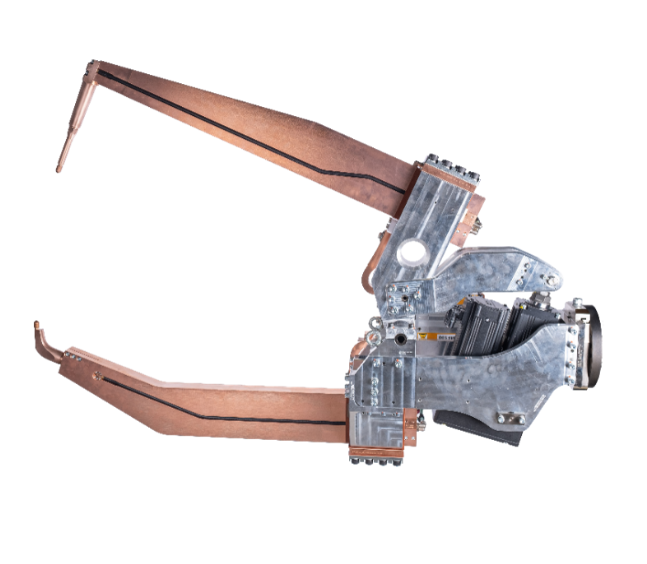

The Basic XL-Gun is a robot welding gun for steel welding with X-frame that has an extra-large welding window. Its max. welding force is 8.000N

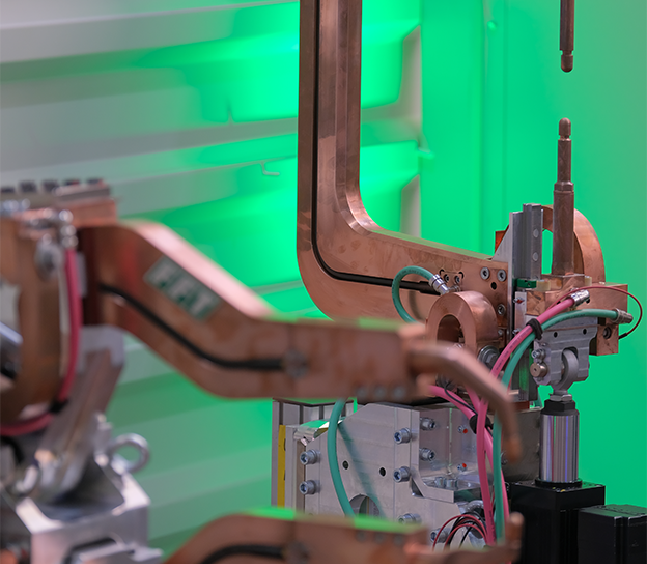

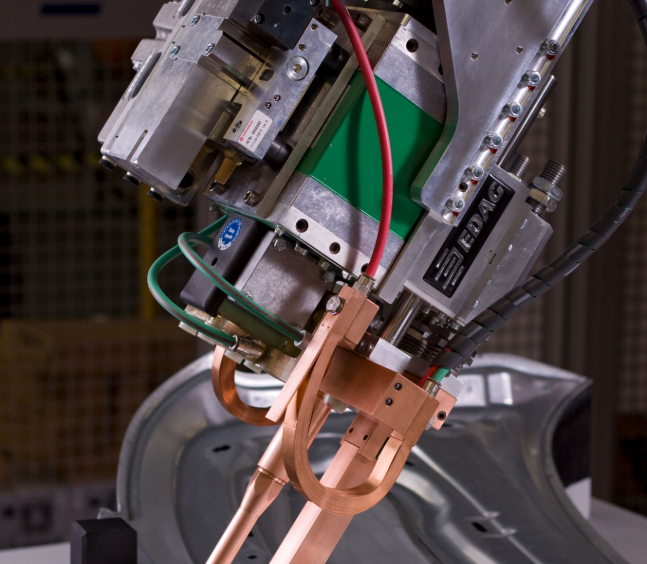

The Advanced C-Gun is a robot-welding-gun-series for aluminum welding not only for the automotive industry.

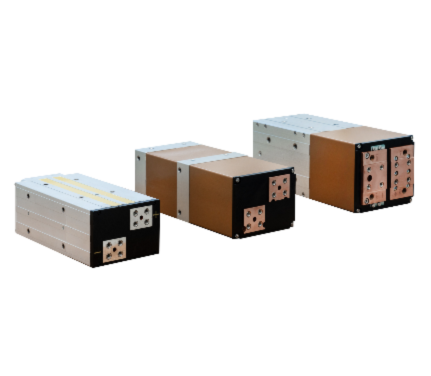

Our transformer product has high welding efficiency and fast welding speed, which can be used for welding various materials. It adopts a lightweight structural design, and the rectifier is detachable for quick replacement. The appearance meets ISO standards and can be adjusted according to customer needs.

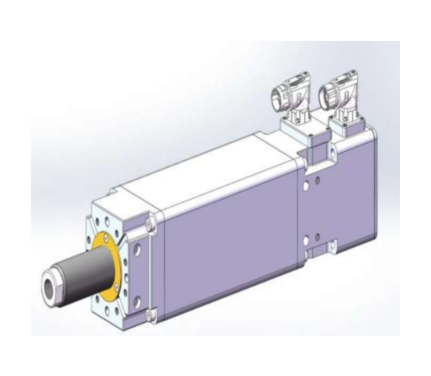

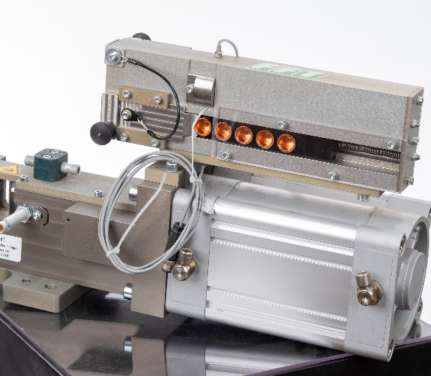

The Actuator can match most mainstream industrial robots on the market and is widely used in fields such as new energy vehicle manufacturing, mechanical equipment manufacturing, automation equipment manufacturing, locomotive and subway manufacturing, energy equipment manufacturing, etc

The TipChanger (TC) enables time-optimized and automatic changing of electrode caps on robot-guided welding guns. It combines minimum space requirements with optimum accessibility for the robot. The electrode caps are changed one after the other without reorienting the welding gun. The cap magazine is mounted in the same orientation as the change tool. The fill level in the cap magazine and cap present / removed are queried via inductive sensors. The loosened electrode caps automatically fall into a collecting basket.

Mobile TipChanger (MECC) enables time-optimized and automatic changing of electrode caps on stationary welding guns. The MECC combines compact design with low weight for mounting on the robot gripper. The electrode caps are changed one after the other by aligning the MECC to the stationary welding gun. The cap strips of the magazine unit can be preloaded outside the system. The fill level in the cap magazine and the cap present / removed is monitored via sensors. The cap magazine is mounted in the same orientation as the changing tool, no reorientation of the MECC is necessary for the changing process. The position of the wedge separator is sensed by sensors. After replacement, the electrode cap is taken away and released by the robot above a specified position (above a collection container).

The VarioPicker® EVO is primarily used for hemming fixation in an automated, robot-guided joining process. Permanent fixation points are created, eliminating the need for tack welding after the hemming process.The fixation points set by the VarioPicker® EVO serve to connect the outer shell to the support structure. A dedicated service station ensures the process reliability of the VarioPicker® EVO.

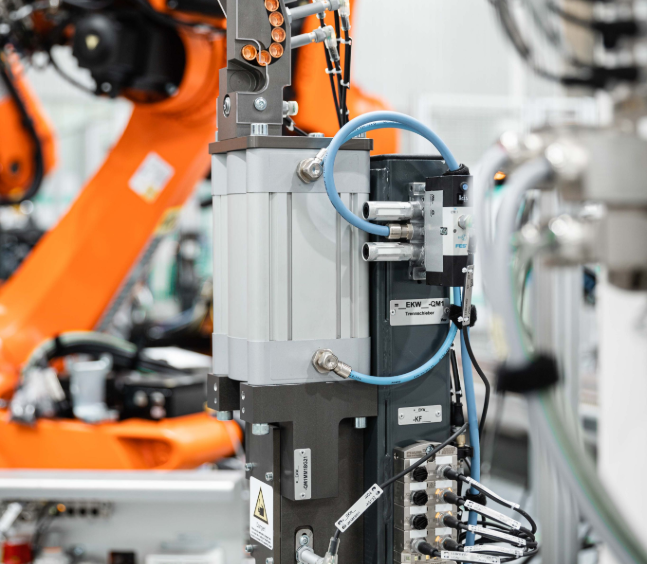

As your service partner for the design of resistance spot welding tools, we specialize in the design and development of weld guns, including product-specific geometries tailored to customer specifications and guidelines. Our services encompass the creation of measurement and test protocols, as well as the design of custom welding machines engineered to meet precise customer requirements. Additionally, we develop electrode cap changing systems (EKW) and configure optimal welding parameters for each specific application. To ensure performance and reliability, we also create simulation models for comprehensive analysis in accordance with customer specifications.

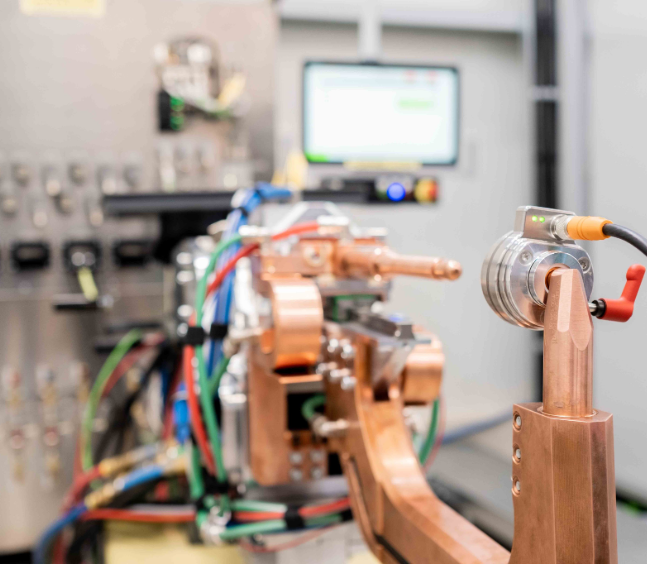

The weldtec Test Station enables professional and comprehensive testing of robot guns across various designs. By conducting tests after maintenance or repairs, potential deviations can be identified and corrected, helping to prevent unplanned downtime during ongoing production. The inspection process ensures that any irregularities are detected and resolved efficiently. Upon completion of each inspection, the system automatically generates a detailed report and securely stores all collected data. This approach leverages the required robot controls to ensure optimal performance and reliability.

With the measuring station, robot guns of various designs can be professionally and extensively checked and calibrated. By measuring the robot guns after maintenance or repair, deviations can be detected and adjusted, and downtimes in the system during ongoing production can be avoided if necessary. Deviations can be detected and eliminated during the inspection. At the end of each measurement, a report is generated and the data obtained is saved. No robot controls are used with this concept.

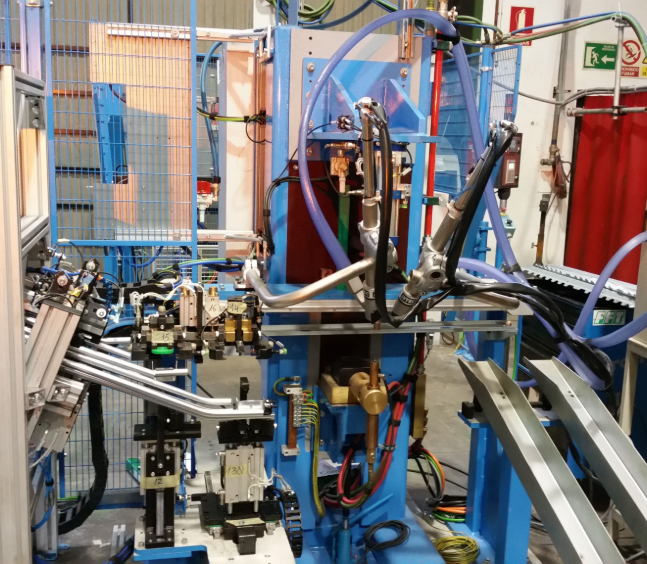

The Inline Projection Welding Machine is able to weld many different kind of components (nuts, bolts, plates...) automatically, avoiding manual intervention and ensuring the correct positioning of the component. The Inline Projection Welding Machine is installed inside a production line and can be controlled by the PLC line.

There is a second option where the machine is controlled by its own PLC. There is the Robot version, which feeds the nuts/bolts or parts to be welded ensuring the correct position in the part. With this solution we could save lot of space in the layout, and we could feed different nuts/bolts with different orientations in just one machine.

The Offline Projection Welding Machine is able to weld many different types of components (nuts, bolts, plates...) in one manual weld. The Offline Projection Welding Machine is installed outside a production line. There is the Automatic version, which works without operator and can produce about 20-30 pieces in automatic mode. One operator can drive several automatic machines at the same time.

The machine has its own PLC and a mobile HMI to control the machine. Thanks to our common tool, it is possible to change the tool quickly and easily from the machine, allowing other parts and components to be welded at the same machine.

Recently, Easun Technology has discovered that illegal individuals have impersonated our company to post fraudulent recruitment information on platforms such as Zhaopin (智联招聘) and Liepin (猎聘). To protect the legitimate rights and interests of job seekers, we hereby solemnly declare:

1. All official recruitment information from Easun Technology is exclusively released through our official website and verified accounts on recruitment platforms. We strongly advise job seekers to verify information solely through these authorized channels and to remain vigilant against unverified sources.

2. Do not disclose personal information (including but not limited to ID numbers, bank accounts, or contact details) to any unofficial channels. Unauthorized sharing may lead to potential risks or financial losses. No fees or transfers are required during Easun Technology’s recruitment process. If any party requests payment under the guise of recruitment, cease communication immediately and report the incident to local authorities.

3. Legal actions are underway: We have formally reported these fraudulent activities to the public security authorities and will fully cooperate with investigations to hold accountable those responsible for violating the law.

4. Easun Technology remains committed to providing authentic and reliable employment opportunities and safeguarding a trustworthy recruitment ecosystem. We appreciate your continued support and vigilance.

Issued by: Easun Technology

Date: 7 Jan 2025