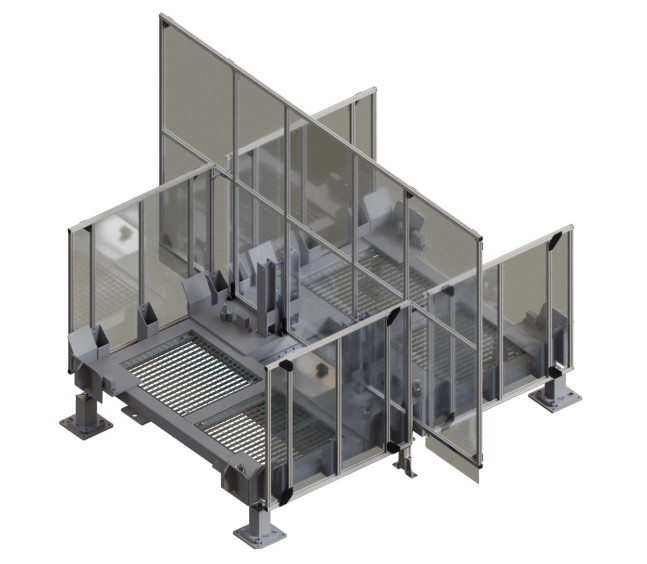

The Rack Changer T is an automated solution to decouple the cycle time by infeed and outfeed of large parts in production lines with containers. After the changeover, the turntable is automatically rotated by 180°.

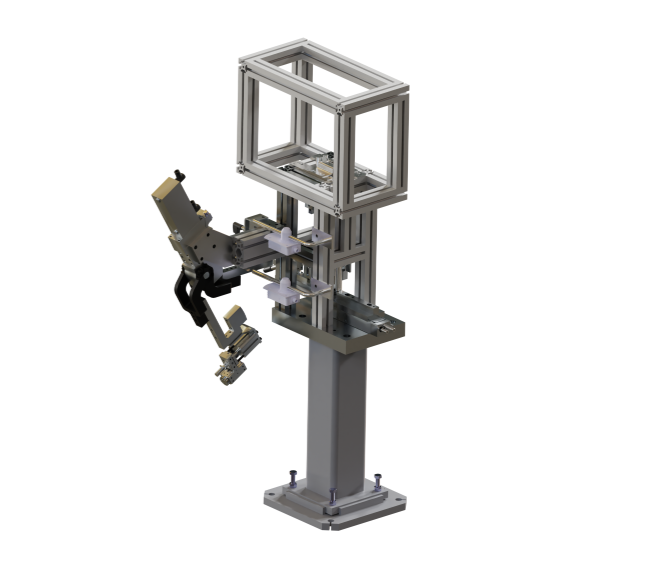

The Part Feeder is a simple solution for feeding small components into the production process. Safety checks are not necessary with the part feeder as it is part of the mechanical safety circuit.

With the Part Feeder, separation is realized either by the component itself, by latches or by a pre-holding system. The inserted components are fed to the different variants by gravity using the angle of attack of the feed section. The guidance of the components ensures that nothing is wedged or deformed. Incorrect operation is avoided by installing the so-called poka-yoke technology.

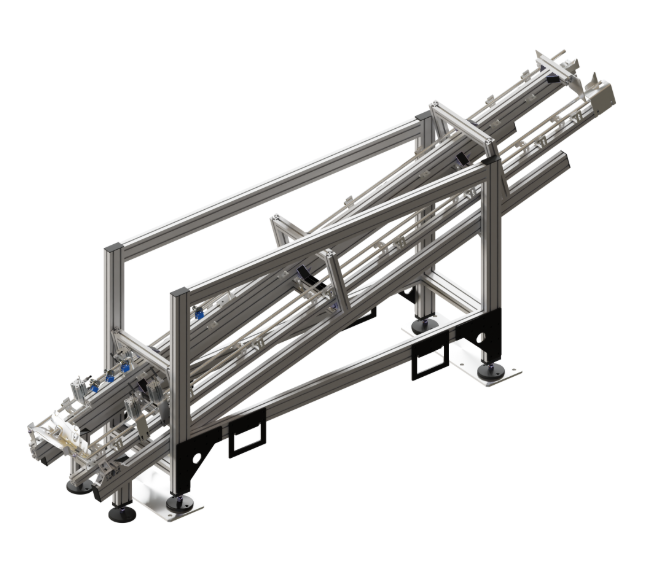

The Part Feeder RS is a simple solution for feeding small parts to the production process by gravity based on their outer contour. High buffer capacity in a small installation space enables a long decoupling time.

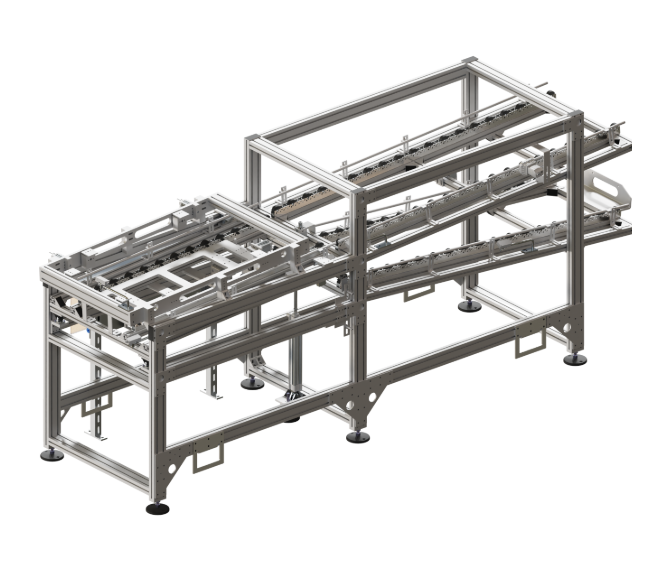

The Part Feeder B is a simple solution for feeding small parts into the production process within a container. In addition, the empty containers are automatically removed back to the operator.

The Part Feeder V is a simple solution for feeding a big amount of small parts into the production process. Due to the vertical part buffer a limited space is required.

Recently, Easun Technology has discovered that illegal individuals have impersonated our company to post fraudulent recruitment information on platforms such as Zhaopin (智联招聘) and Liepin (猎聘). To protect the legitimate rights and interests of job seekers, we hereby solemnly declare:

1. All official recruitment information from Easun Technology is exclusively released through our official website and verified accounts on recruitment platforms. We strongly advise job seekers to verify information solely through these authorized channels and to remain vigilant against unverified sources.

2. Do not disclose personal information (including but not limited to ID numbers, bank accounts, or contact details) to any unofficial channels. Unauthorized sharing may lead to potential risks or financial losses. No fees or transfers are required during Easun Technology’s recruitment process. If any party requests payment under the guise of recruitment, cease communication immediately and report the incident to local authorities.

3. Legal actions are underway: We have formally reported these fraudulent activities to the public security authorities and will fully cooperate with investigations to hold accountable those responsible for violating the law.

4. Easun Technology remains committed to providing authentic and reliable employment opportunities and safeguarding a trustworthy recruitment ecosystem. We appreciate your continued support and vigilance.

Issued by: Easun Technology

Date: 7 Jan 2025